Safety Signs

Component signs

BS ISO 3864-1:2011, specifies that a combination sign be used only to further improve comprehension of the sign. This is to ensure that occupants are left with more information rather than confusion. JALITE photoluminescent component signs provide occupants, trained personnel, visitors, and emergency services with additional information. JALITE photoluminescent component signs are letter and number characters signs that can be used alongside assembly points and firefighting equipment, such as fire alarm call points.

Where there are more than one assembly point or fire point, JALITE photoluminescent component signs are installed with existing signs, to help specify the number of the equipment. For example, an assembly point could be labelled ‘Assembly point 2’. During an emergency evacuation, JALITE photoluminescent component signs can ease the evacuating process by limiting confusion and congestion of the assembly point. Evacuees already assigned to assembly point 2, can quickly and easily proceed once this area is labelled. JALITE photoluminescent component signs are available in different sizes, to be affixed with existing JALITE signs.

Quick overview

Characteristics

BS ISO 17398:2004 - Safety colours and safety signs. Classification performance and durability of signs.

This International Standard specifies requirements for a performance-related classification system for safety signs according to expected service environment, principal materials, photometric properties, means of illumination, fixing methods and surface. Performance criteria and test methods are specified in this International Standard so that properties related to durability and expected service life can be characterized and specified at the time of the product’s delivery to the purchaser.

DIN 67 510 Part 1: 2020 - Phosphorescent pigments and products - measurement and marking at the producer.

This standard applies to the measurement and classification by the manufacturer of phosphorescent pigments and the phosphorescent products made from them, for example for marking escape routes and hazards, in buildings, underground thoroughfares, on aircraft and ships, for marking equipment, fittings, utensils, working clothing and safety clothing. This standard specifies a series of conditions for testing the change in luminance over time and for identifying the tested phosphorescent products.

BS ISO 3864-1:2011 - Graphical symbols - Safety colours and safety signs - Part 1: Design principles for safety signs and safety markings.

This part of ISO 3864 establishes the safety identification colours and design principles for safety signs and safety markings to be used in workplaces and in public areas for the purpose of accident prevention, fire protection, health hazard information and emergency evacuation. It also establishes the basic principles to be applied when developing standards containing safety signs.

BS ISO 3864-3:2012 - Graphical symbols - Safety colours and safety signs - Part 3: Design principles for graphical symbols for use in safety signs.

This part of ISO 3864 establishes the safety identification colours and design principles for safety signs and safety markings to be used in workplaces and in public areas for the purpose of accident prevention, fire protection, health hazard information and emergency evacuation. It also establishes the basic principles to be applied when developing standards containing safety signs.

BS ISO 3864-4:2011 - Graphical symbols - Safety colours and safety signs - Part 4: Colorimetric and photometric properties of safety sign materials.

This part of ISO 3864 establishes the colorimetric and photometric requirements and test methods for the colours of safety signs to be used in workplaces and public areas. It provides the colorimetric and photometric specifications for the named safety and contrast colours prescribed in ISO 3864-1. The physical requirements that safety signs have to meet are primarily related to daytime colour and normally lit environments. This part of ISO 3864 also includes the colorimetric requirements and test methods for safety signs and phosphorescent material which also operate in unlit environments.

BS 5499-10:2014 - Guidance for the selection and use of safety signs and fire safety notices

This part of BS 5499 provides guidance on how to select, install, position and maintain safety signs conforming to BS ISO 3864‑1 and BS EN ISO 7010, excluding escape route signs, to present specific safety information. Fire safety notices are also covered in Annex A.

UNIQUE PRODUCT CODES

Each JALITE sign has a unique code number, after the sign code you will see the size code as shown in the example below.

Code Example: 435T

| Sign Code | Size Code |

| 435 | T |

SIGN TYPES

JALITE offer a range of sign types, single sided, panoramic signs, double-sided wall mounted signs and double-sided hanging signs.

VIEWING DISTANCE

The expected viewing distance of a safety sign is described according to the Z factor. The Z factor is the ratio of the viewing distance divided by the sign height (graphical symbol height plus geometric shape according to BS EN ISO 7010:2020 image) - Direct line of sight.

SAFETY SIGNS COLOURS & SHAPES

The standard BS ISO 3864-1:2011 specifies a system of geometric shapes and safety colours for use with the appropriate graphical symbols to produce safety signs.

MATERIAL CODES

The following materials are used to manufacture JALITE products.

|

MATERIAL |

PREFIX |

SUFFIX |

|

JALITE AAA |

~ |

R |

|

White rigid PVC |

W |

R |

Code Example: White exterior rigid pvc - WX6420ER

| Prefix | Code | Size | Suffix |

| WX | 6420 | E | R |

CODE SIZE’S FOR SIGNS Note: Please check sign for available sizes.

| CODE | SIZE (mm) |

| C | 150 x 150 |

| P | 75 x 150 |

| G | 150 x 300 |

| Q | 300 x 300 |

Let's save lives together - you and us!

More Solutions

Floorings - Safety floorings

Learn more

Safety Signs - Tie tag

Learn more

Safety Signs - Prohibition

Learn more

Safety Signs - Emergency Equipment

Learn more

Safety Signs - Escape route signs

Learn more

Safety Signs - Mandatory Instruction

Learn more

Safety Signs - Marine

Learn more

Safety Signs - Fire Fighting Equipment

Learn more

Safety Signs - Warning

Learn more

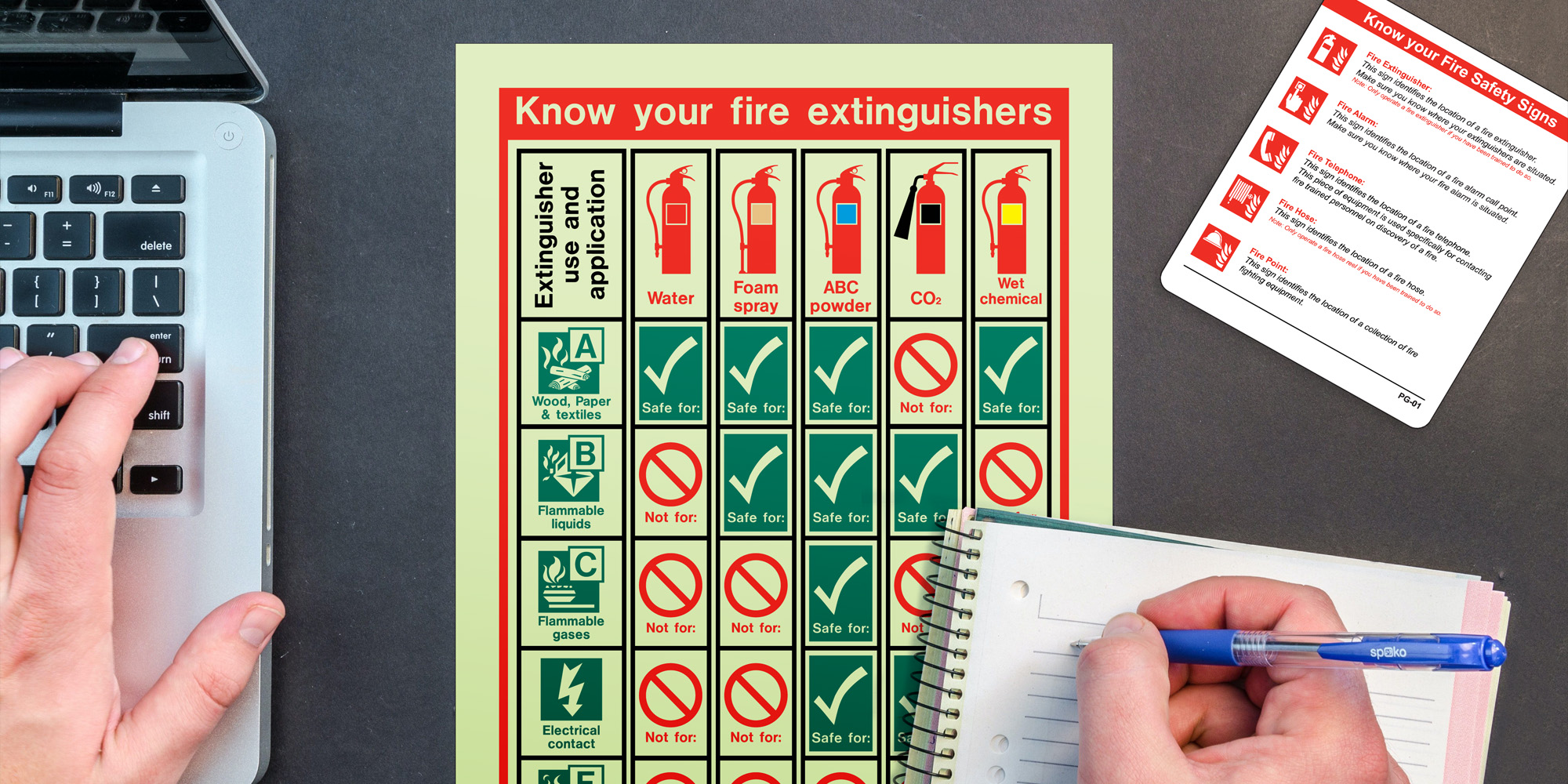

Safety Training Products

Learn more

Safety Way Guidance Escape route marking

Learn more

International Wayguidance

Learn more

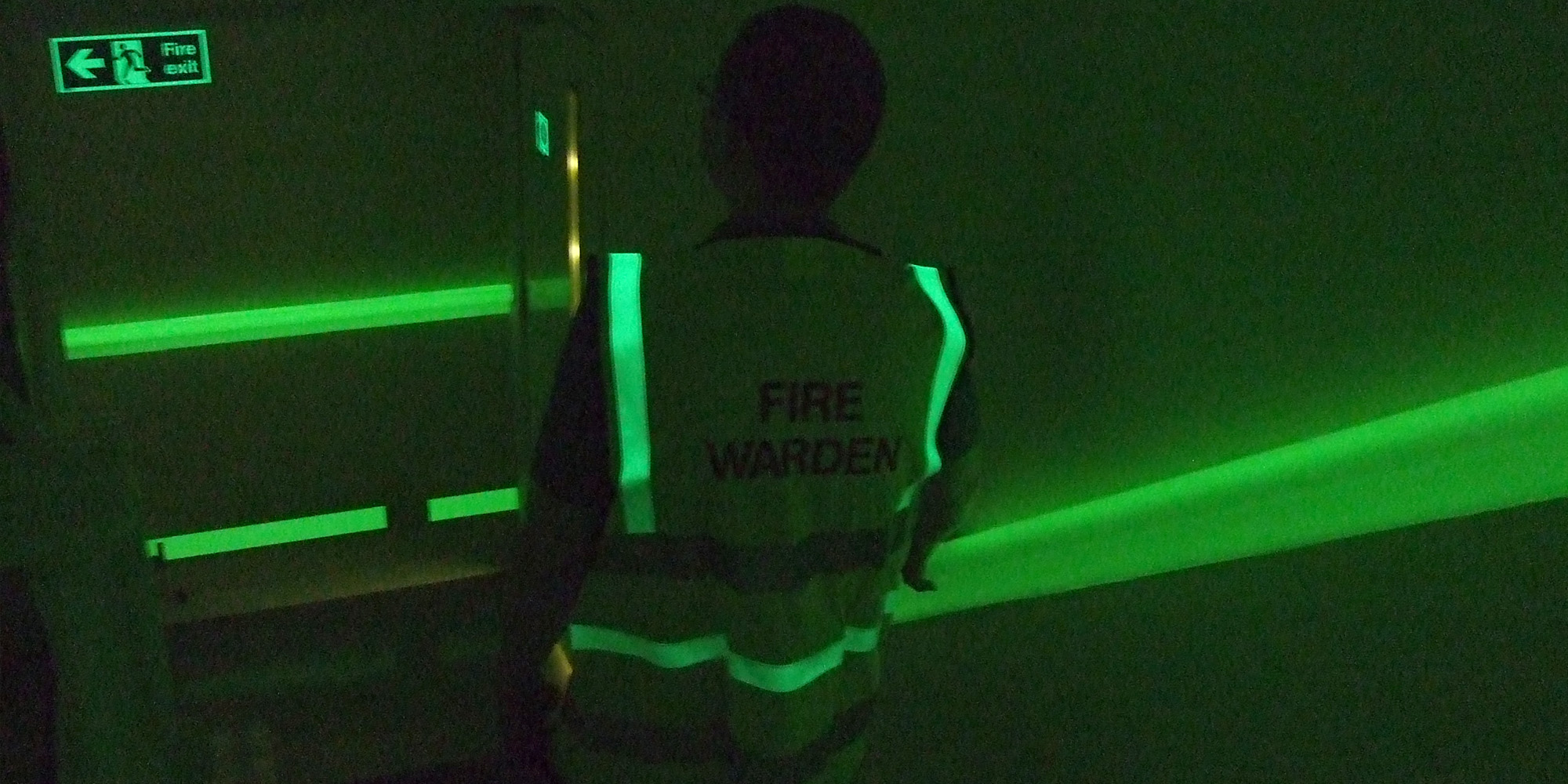

Clothing - Evacuation safety products

Learn more

Coatings

Learn more

Evacuation Safety Products and Tapes

Learn more

Facilities management Signs

Learn more

Frames Fixtures and Fittings

Learn more

Materials

Learn more

Ordinary

Learn more

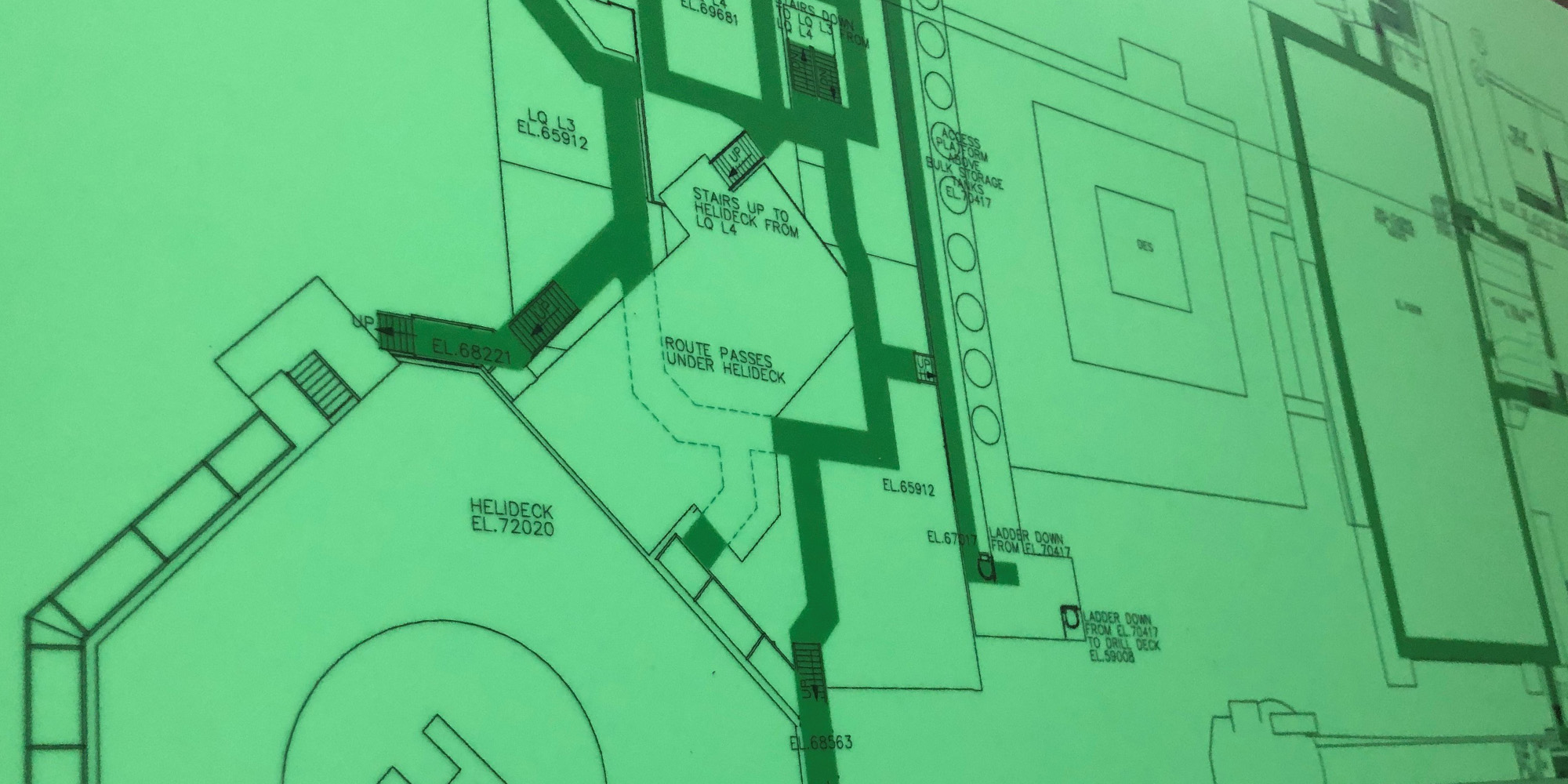

Safety plans (signs)

Learn more

Disability Signs & DDA Signage

Learn more

Marine & Offshore Signs & Notices

Learn more